Service hotline

(+86) 738-831 9168

Project background

With the rapid development of the automotive electronics and automation industry in recent years, the application of supporting solenoid valves and relay products has developed rapidly. In the process of new product development, relevant companies urgently need to conduct evaluation of magnetic material selection, quality control of magnetic materials and components, and magnetic component manufacturing processes. Evaluation, etc. to establish effective detection means.

Needs analysis

The process of solenoid valve and relay products from R&D to mass production mainly includes four aspects: material selection, magnetic circuit design (finite element analysis), magnetic material or component quality inspection, and magnetic parts process improvement evaluation.

⑴ Material selection: Select different materials according to product requirements for testing to obtain the basic magnetization curve of the material.

⑵ Magnetic circuit design (finite element analysis): The equipment can provide the original data of the magnetization curve. When designing the magnetic circuit, it can be directly imported into design software such as finite element analysis for magnetic field simulation to improve design and R&D efficiency. When designing, you can select data from multiple materials for simulation comparison and select matching materials.

⑶ Quality testing of magnetic materials and components: Material production and application companies have clear magnetic performance evaluation indicators when materials and components enter and leave the factory. Through testing, they can accurately evaluate whether the materials are qualified and whether the consistency of the materials meets the requirements.

⑷ Process evaluation: After the soft magnetic material is processed, the external force during processing will cause stress inside the material, which will affect the magnetic properties of the material (especially the magnetic permeability and coercivity), which usually requires Heat treatment is used to eliminate stress generated during material processing. At this time, the material process can be evaluated by measuring the magnetic parameters of the material. On the contrary, in some specific application fields of magnetic devices, because the processing accuracy of parts is extremely strict, in order to avoid the deformation of parts caused by heat treatment, heat treatment is usually not performed. Engineers will try to compare various processing methods to reduce the number of parts during the processing. On the impact of magnetic properties of materials, testing the coercivity of parts to compare the impact of different process conditions on the magnetic properties of materials is undoubtedly a very intuitive and effective detection method.

Solution

1. Test equipment

MATS automatic testing system for magnetic materials: The system integrates MATS-2010SD soft magnetic DC measurement device and CIM-3200 soft magnetic material coercivity

Two subsystems of the force measuring instrument.

2. Equipment functions

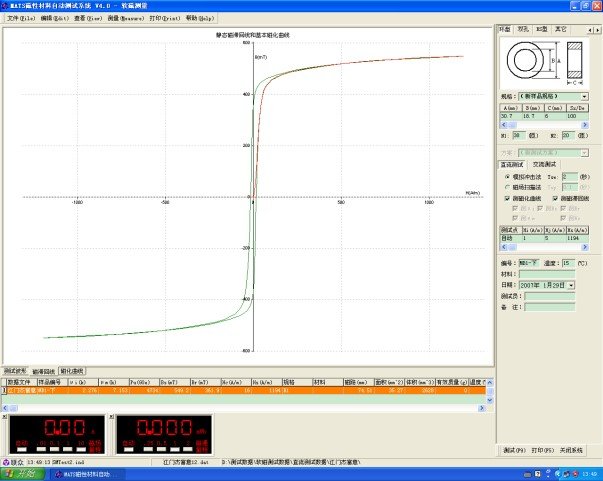

⑴ MATS-2010SD soft magnetic DC measurement device can automatically measure the basic magnetization curve and hysteresis loop of soft magnetic materials under static (DC) conditions, and accurately measure the initial magnetic permeability μi, maximum magnetic permeability μm, and saturation magnetic induction. Static magnetic characteristic parameters such as strength Bs, remanence Br, coercivity Hc and hysteresis loss Pu.

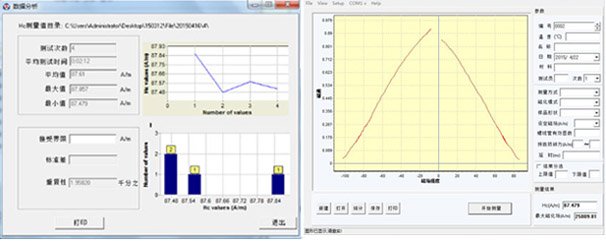

⑵ CIM-3200HC soft magnetic material coercive force measuring instrument can be used to measure the coercive force of strip, rod or sheet samples and soft magnetic workpieces.

3. Test scope

Test parameters sample shape

MATS-2010SD initial magnetic permeability μi

Maximum magnetic permeability μm

Saturation magnetic induction intensity Bs

Residual magnetic induction intensity Br

Coercive force Hc

Hysteresis loss Pu

B(H) magnetization curve

B(H)hysteresis loop

μ(H) magnetic permeability curve circular shape

EE/EI type

UU/UI

rectangle

CD type

double hole

…

CIM-3200HC coercivity Hc strips, sheets and

Rod-shaped soft magnetic parts

4. Software interface

⑴ Soft magnetic test interface

⑵ Coercive force test interface

If you have any questions, please contact us!

ContactUs

©2000-2024 Hunan Linkjoin Technology Co., Ltd. All Rights Reserved. XML map

address:No. 20, Chuangxin Third Road, the Second Industrial Park, Economic Development Zone, Loudi, Hunan,China